3D printing the future of fusion energy

TAE’s added dimension

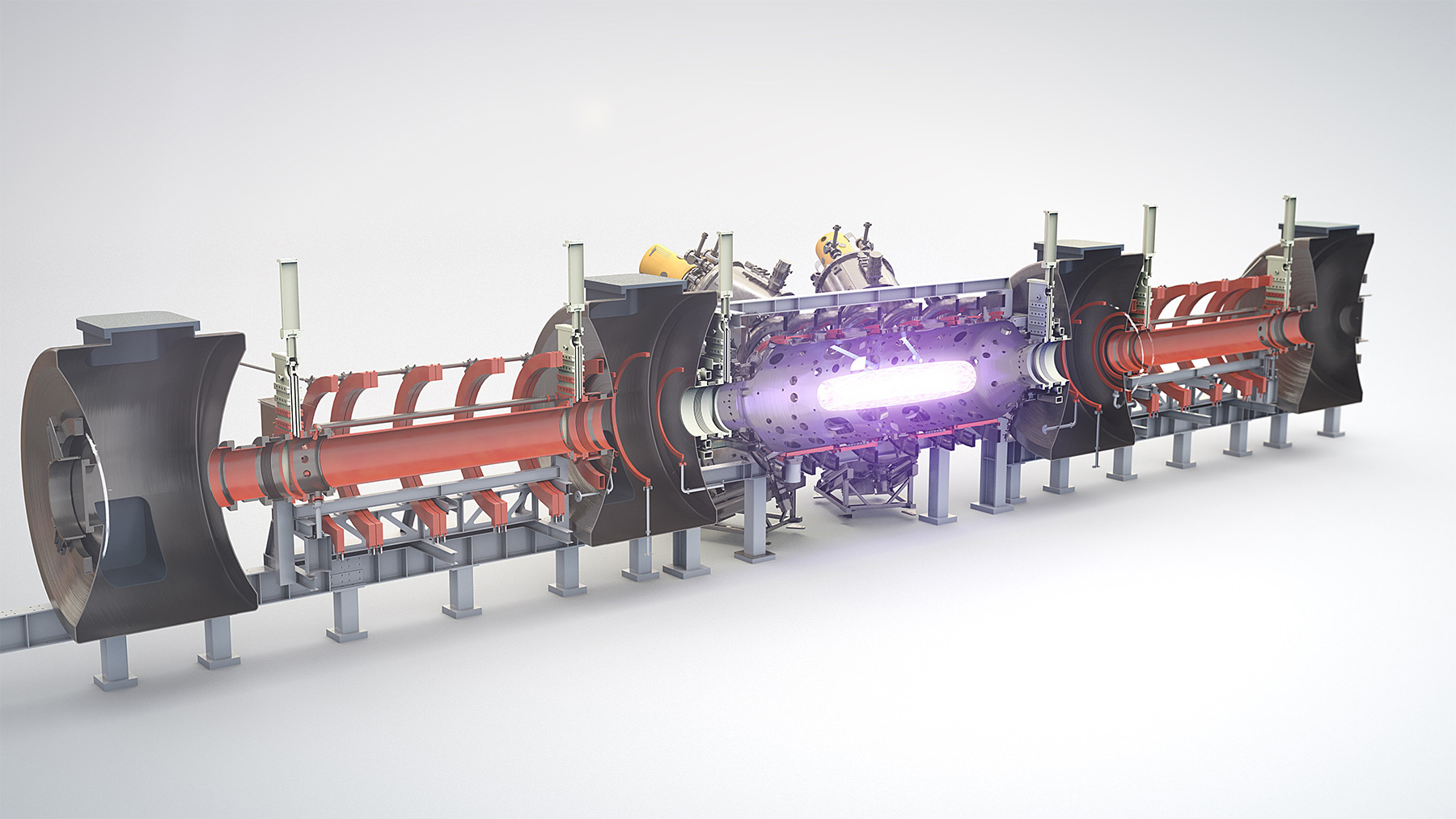

Interior rendering of TAE’s fifth-generation fusion research reactor Norman, which operates at more than 70 million degrees Celsius.

Since its founding in California in 1998, TAE has built five generations of fusion platforms using a proprietary and scientifically proven approach to clean fusion power, which the company expects to commercialize by the early 2030s.

Through a partnership with EOS North America, TAE uses additive manufacturing to develop design solutions and build prototypes for its next-generation fusion research reactors.

Watch the video below to see a 3D printed replica of TAE’s sixth fusion machine, Copernicus.

Meet Copernicus

Faster progress with less waste

- Greater design speed 3D printing enables TAE to quickly print several iterations of components, generating fast resolutions to complex problems.

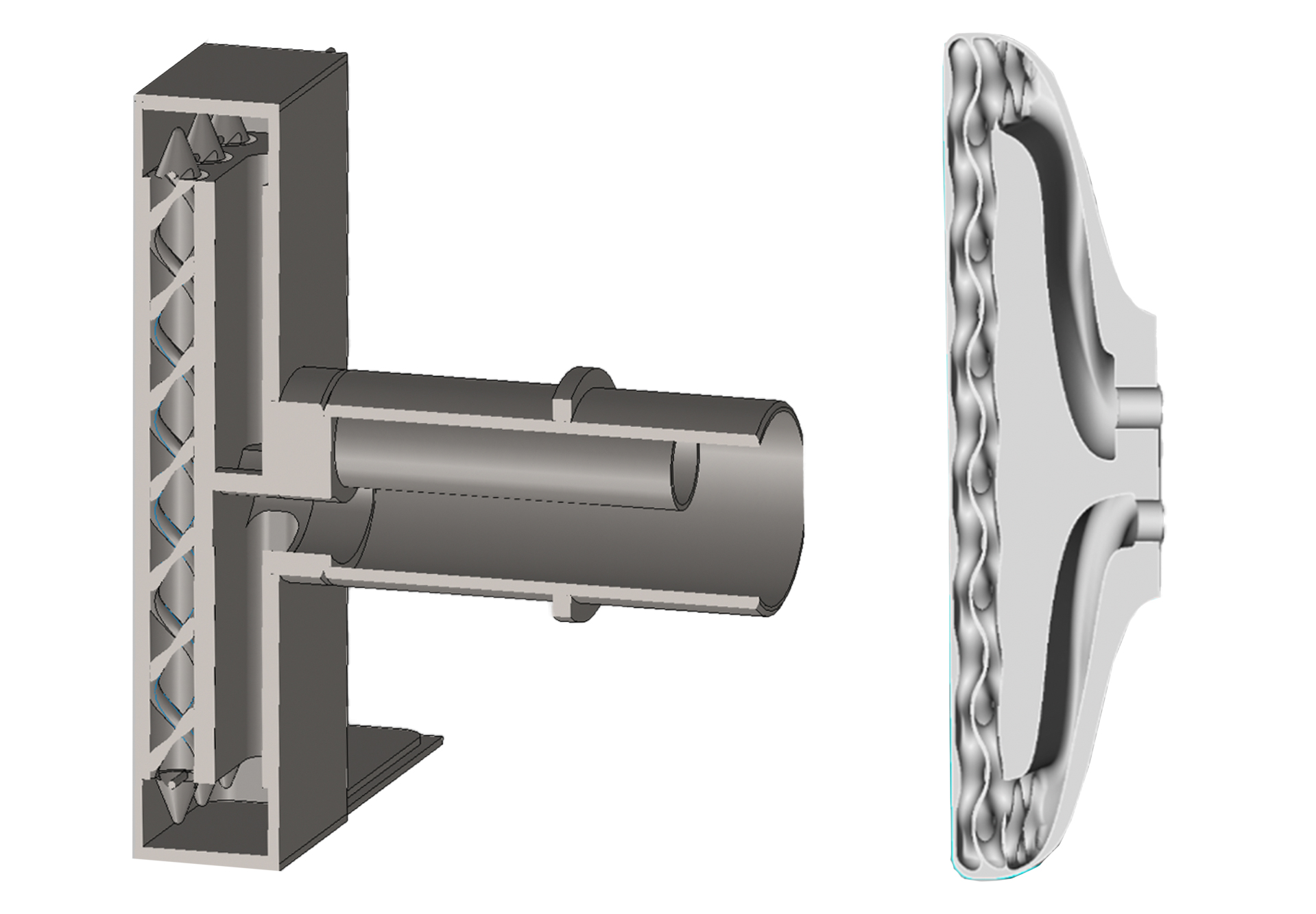

AM design offers more organic geometries and simplified manufacturing (right) compared to conventionally manufactured components (left).

- Manufacturing efficiency AM doesn’t require traditional welding and inspections, eliminating hours of work compared to conventional manufacturing.

- Sustainable materials use 3D printing cuts the weight of some components in half, improving assembly, maintenance and ergonomics. Lighter weight also means less material needed for manufacturing, reducing cost and environmental impact.

A photo of a 3D printed research reactor component, at 2kg half the weight of what it would be with conventional manufacturing.

- Innovation for the energy transition AM solutions are also being evaluated to play a role in the future fusion supply chain. To meet global energy demand, nuclear fusion power plants will need to be built around the world – and the speed and economical production pipeline 3D printing can offer will be vital.