Step inside TAE’s fusion research lab

From our control room to our accelerator beams, take a virtual tour of TAE’s unique approach to fusion in 6 photos.

With our teams laser-focused on delivering commercial hydrogen-boron fusion power, we don’t often have the opportunity to open our doors to the public.

But as part of US Fusion Energy Week, we were able to offer a rare look inside our California lab. In a virtual tour guided by our CEO Michl Binderbauer, attendees got a closer view of the proprietary fusion technology that has propelled TAE toward net energy generation – including our fifth-generation fusion research reactor, Norman.

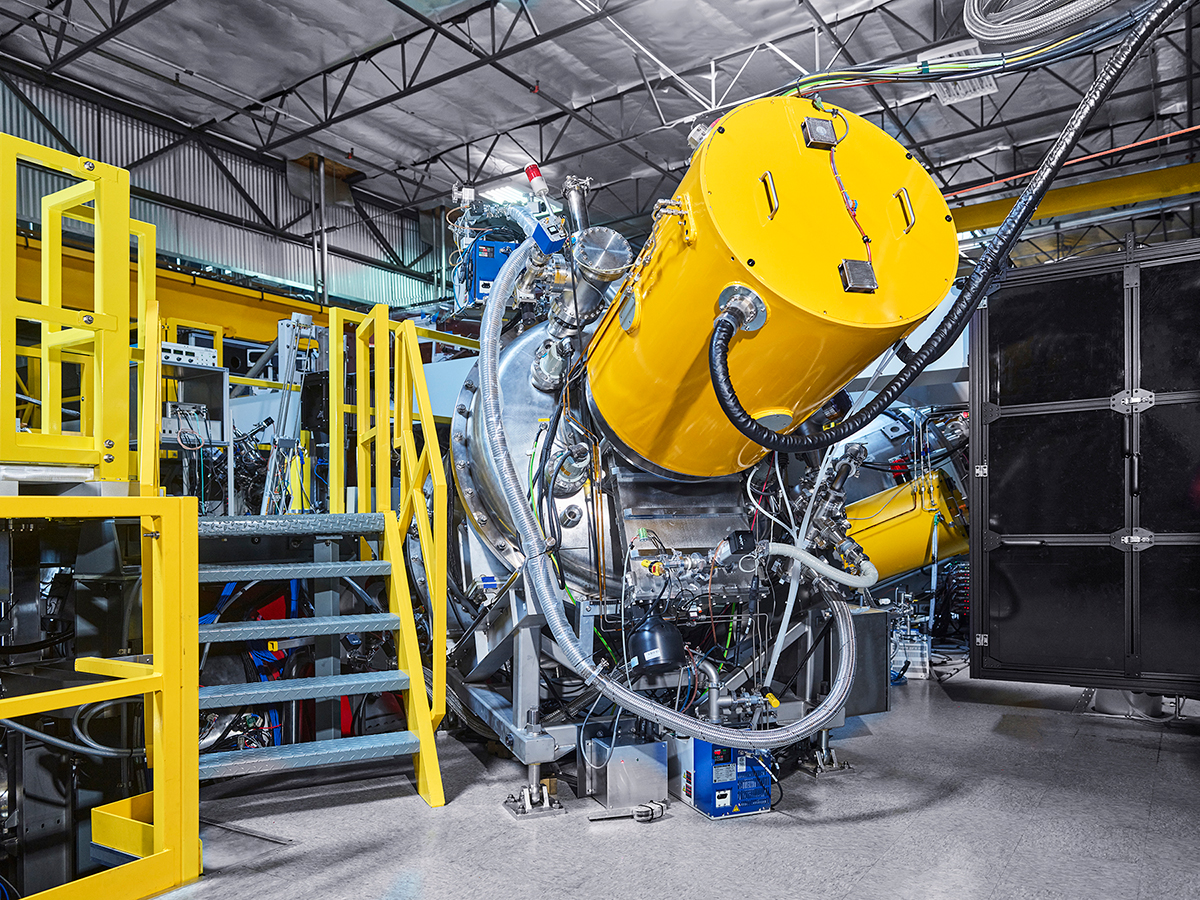

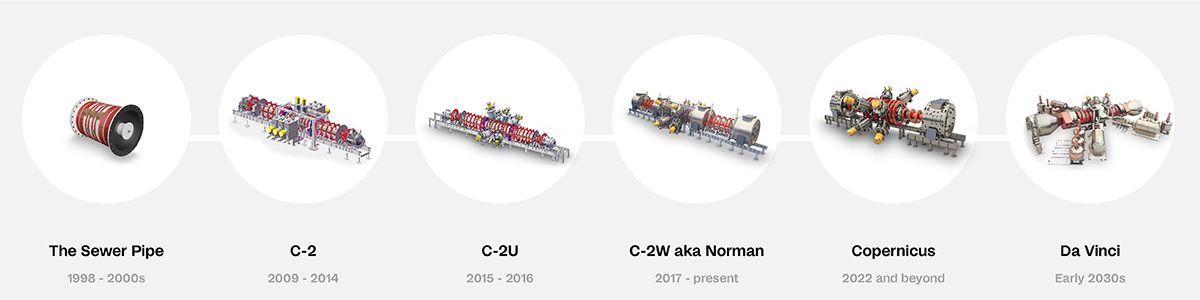

Built from scratch in 2016, Norman is the fifth installment on our roadmap of seven devices to create a prototype fusion power plant. The machine was designed to prove that our technology could maintain plasma at the temperatures needed to scale up to reactor-level performance.

Norman has already delivered on this goal – and then some. Today, standing roughly 22 feet tall and 80 feet long, the machine is capable of running up to 1,000 fusion experiments a month at temperatures many times hotter than the core of the sun.

“It’s an incredibly exciting machine,” Binderbauer said of Norman, which is named after TAE’s late technology co-founder, Dr. Norman Rostoker. “It’s an escalation of about 25 years of fusion research, and it’s the machine that gets us to about 75 million degrees … literally a strike away from around the 100 million [degrees] mark. [Norman] is a research device … but it is also at the edge now of getting into the reactor regime.”

If you missed the tour, take your own spin through our lab with these highlights:

What makes TAE so unique

TAE is distinct in its approach to developing commercial fusion power. First, our machine configuration is linear – Norman is a cylindrical device that operates along an axis in contrast to the donut shape of the more conventional tokamak.

Second, our end goal is also different from most: TAE is scaling toward hydrogen-boron fusion, which is the cleanest and safest form of fusion power. Hydrogen and boron are both non-radioactive and incredibly ubiquitous, and when used to generate a fusion reaction the only output would be clean helium gas. While hydrogen-boron fusion has the challenge of a higher temperature than other approaches, we’re pursuing it because we believe hydrogen-boron fusion has the advantages of being a clean, economical and abundant power source for the future of humanity.

How we use machine learning

Norman runs up to 1,000 experiments per month – experiments that are all developed and executed from our command center, a.k.a our control room.

On any given day, a concert of TAE engineers, physicists, diagnostics specialists and technicians converge in this area to orchestrate the next sequence of tests, monitor and evaluate Norman’s plasma performance, and incorporate AI and machine learning to rapidly advance their findings.

“We have one of the most advanced machine learning and AI-enhanced operations of any machine in the fusion space that I’m familiar with,” Binderbauer said on the tour. “There’s a long-standing history between TAE and Google‘s inner research team working on machine learning and other tools to combine the spontaneity and creativity of the human mind and the untiring calculating ability of the computer and its infinite depth of memory. Every prior experiment ever run on Norman or predecessor machines or anything else … is available to the artificial brain, and so it can simulate all that historical learning and bring that to the decision process for each experiment. What we’ve learned is that by combining those two things, you make exponentially the biggest progress.”

Custom-built power supply system

Norman consumes up to 750 megawatts of peak power, comparable to the output of a large-scale utility power plant.

To ensure that we could run Norman efficiently and sustainably without burdening our local resources, our team invented a power storage solution that allows us to store energy from the grid in between experiments and then release it to Norman in precise, high-power pulses.

This technology has been so effective at keeping the tens of thousands of electrified parts of Norman operational that it’s become the foundation of our TAE Power Solutions spinoff, a company that launched in 2023 to supply more intelligent power management solutions to an increasingly electrified world.

Why we use accelerator beams

The yellow cylinders surrounding the body of our Norman device are part of our patented particle accelerator technology and a cornerstone of TAE’s approach to commercial fusion. “If you were to look at those inside, they look a little bit like a rendition of a lightsaber out of ‘Star Wars,’” Binderbauer said on the tour. The cylinders are “essentially atom guns” that provide an “injector system that is essentially a collimated beam of neutral hydrogen atoms.”

With TAE’s proprietary advanced beam-driven Field-Reversed Configuration (FRC), plasma forms on each side of the machine and is accelerated toward the center, where it becomes a hollow, football-esque shape in the fusion device’s magnet-lined containment vessel. The accelerator beams are used to inject neutral atoms to drive current as well as heat and stabilize the plasma.

After spending more than 20 years developing this fusion technology, we’ve uncovered other uses that can also improve quality of life: In 2017, TAE created its first subsidiary, TAE Life Sciences , to adapt our accelerator-based fusion fuel injector technology for a biologically targeted cancer treatment based on Boron Neutron Capture Therapy (BNCT) for complex and often inoperable cancers.

How we keep our experiments pristine

In order to perform our experiments, our fusion device has to be kept immaculately clean of any and all particulates that may blow into our workspace.

That’s where the cylindrical silver divertors – the part of Norman you’re used to seeing in photos – come in.

Those are part of a vacuum system that’s capable of pumping about 2 million liters of gas per second. “If they were designed for atmospheric conditions, you could literally evacuate the air in [our] entire machine hall in about a second with one of these pumps,” Binderbauer said. “So there’s a lot of pump speed there, and that allows us to get to a very, very high quality vacuum” that can rid Norman of any particles we don’t want interfering with a fusion research experiment.

From Norman to viable fusion power

Norman has significantly advanced our fusion research in its seven years of operation, helping TAE progress toward the cleanest form of commercial fusion power.

“The intent,” Binderbauer said, “is to have a clean, scalable solution that can help humanity enter deeper into an exciting era of fusion as part of the electricity generation mix, allowing us to rid ourselves of some of the carbon-emitting systems we have today and enabling a world of more abundance.”